EPDM Cold Shrink Tube

- Products ID.: EPCS-**X**(**=Dia. of core, ##=Length after shrinkage)

- Spec.: Diameter range 0-165mm, length range 0-1000mm

- Features: Easy to install, no tool required, resistant to weather and UV aging, long-term tight sealing, suitable for power cable below 1kV. Substitution to 3M 8420 series

- Related Products: Silicone cold shrink tube

Description

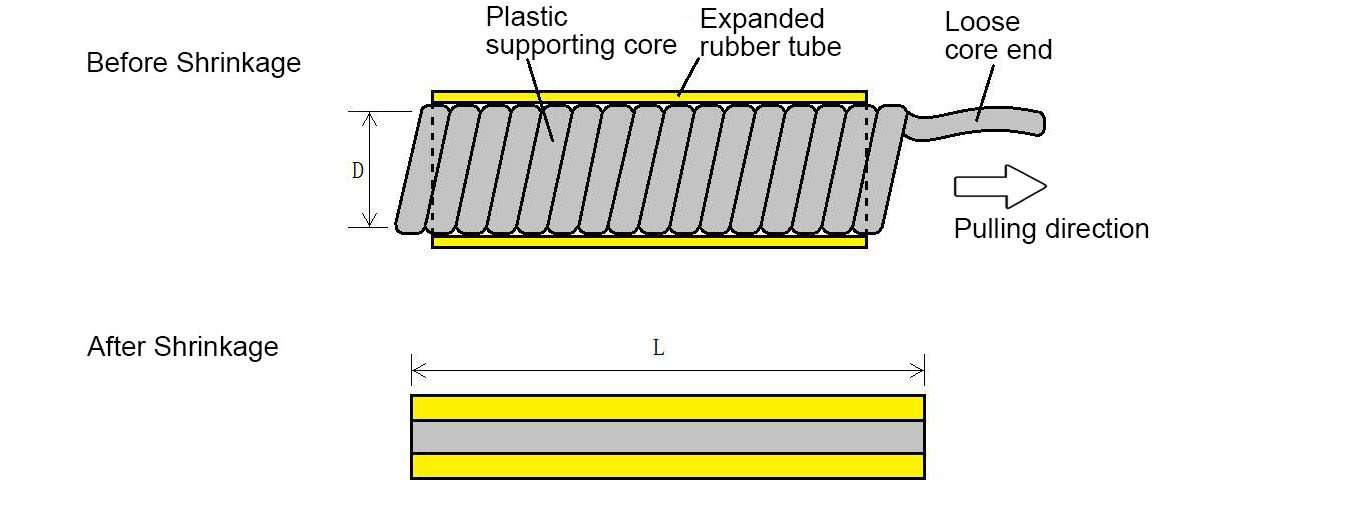

EPDM cold shrink tube is a kind of pre-expanded in the removable supporting core. When in use, it’s only necessary to remove the supporting core after positioning and use its radial pressure to form a covering for cable, which plays the role of waterproof and moisture-proof sealing. Cold shrink tube has excellent weather resistance, acid, and alkali resistance, and achieves the effect of sealing with the breath.

It’s an ideal sealing product for communication cables, coaxial cables, medium and low voltage power cables.

It can also be used as a handle grip sheath, such as for hammer, spanner, ax, garden tools, and sports tools, which play a role in preventing slip.

Features & Advantages:

- Compared with heat shrink tube, it’s more resistant to weather and UV aging, and will not become brittle after long-term use.

- Compared with the silicone rubber cold shrink tube, it’s more resistant to puncture, wear, acid and alkali.

- Synchronized thermal expansion and contraction with the workpiece in harsh environments, no gaps.

- The sealing effect is still excellent with the workpiece in the state of wind blowing and swing.

- Suitable for power cables below 1kV, suitable for a wide range of specifications, can be used for indoor and outdoor, overhead.

- Can be used in water or buried

- Strong resilience, permanent radial pressure, and long-term tight sealing of cables.

- Easy to install, no need for heating or special tools, no need for hot melt glue or tape to strengthen the seal at the joint.

Technical Data:

| Property | Unit | Typical Value | Test Method |

| Shore Hardness | Shao A | 49 | ASTM D 2240 |

| Tensile Strength | MPa | 9.8 | ASTM D 412 |

| Elongation at Break | % | 720 | ASTM D 412 |

| Tear Strength | kN/M | 27 | ASTM 624 |

| Breakdown Strength | kV/mm | 14.3 | ASTM D 149 |

| Dielectric Constant | 5.0 (original) 5.6 (7 days in 90℃ water) | ||

| Bacteria Resistance | 28 days exposure without growth | ASTM G-21 | |

| UV Resistant | UV irradiation for 2000 hours without aging | ASTM D 149 | |

Structure:

Size Table:

| Product ID | Dia. of Core | Application Range (mm) | Length after Shrinkage | |

| D (mm) | Min. Dia. | Max. Dia. | L (mm) | |

| EPCS-18X80 | Ф18 | 7.8 | 14.3 | 80 |

| EPCS-18X152 | Ф18 | 7.8 | 14.3 | 152 |

| EPCS-18X178 | Ф18 | 7.8 | 14.3 | 178 |

| EPCS-25X178 | Ф25 | 10.1 | 20.9 | 178 |

| EPCS-25X203 | Ф25 | 10.1 | 20.9 | 203 |

| EPCS-25X279 | Ф25 | 10.1 | 20.9 | 279 |

| EPCS-25X305 | Ф25 | 10.1 | 20.9 | 305 |

| EPCS-35X152 | Ф35 | 13.9 | 30.1 | 152 |

| EPCS-35X203 | Ф35 | 13.9 | 30.1 | 203 |

| EPCS-35X229 | Ф35 | 13.9 | 30.1 | 229 |

| EPCS-35X279 | Ф35 | 13.9 | 30.1 | 279 |

| EPCS-42X152 | Ф42 | 16.8 | 35.1 | 152 |

| EPCS-42X203 | Ф42 | 16.8 | 35.1 | 203 |

| EPCS-42X254 | Ф42 | 16.8 | 35.1 | 254 |

| EPCS-42X305 | Ф42 | 16.8 | 35.1 | 305 |

| EPCS-42X406 | Ф42 | 16.8 | 35.1 | 406 |

| EPCS-42X457 | Ф42 | 16.8 | 35.1 | 457 |

| EPCS-50X203 | Ф50 | 23.5 | 43.7 | 203 |

| EPCS-58X152 | Ф58 | 24.0 | 49.3 | 152 |

| EPCS-58X178 | Ф58 | 24.0 | 49.3 | 178 |

| EPCS-58X203 | Ф58 | 24.0 | 49.3 | 203 |

| EPCS-58X254 | Ф58 | 24.0 | 49.3 | 254 |

| EPCS-58X305 | Ф58 | 24.0 | 49.3 | 305 |

| EPCS-58X457 | Ф58 | 24.0 | 49.3 | 457 |

| EPCS-58X610 | Ф58 | 24.0 | 49.3 | 610 |

| EPCS-58HPX254 | Ф58 | 20.5 | 51.0 | 254 |

| EPCS-65X254 | Ф65 | 23.7 | 57.5 | 254 |

| EPCS-77X152 | Ф77 | 32.2 | 67.8 | 152 |

| EPCS-77X178 | Ф77 | 32.2 | 67.8 | 178 |

| EPCS-77X229 | Ф77 | 32.2 | 67.8 | 229 |

| EPCS-77X305 | Ф77 | 32.2 | 67.8 | 305 |

| EPCS-77X330 | Ф77 | 32.2 | 67.8 | 330 |

| EPCS-77X335 | Ф77 | 32.2 | 67.8 | 355 |

| EPCS-77X457 | Ф77 | 32.2 | 67.8 | 457 |

| EPCS-77X550 | Ф77 | 32.2 | 67.8 | 550 |

| EPCS-77HPX330 | Ф77 | 32.2 | 67.8 | 330 |

| EPCS-105X203 | Ф105 | 42.6 | 93.7 | 203 |

| EPCS-105X229 | Ф105 | 42.6 | 93.7 | 229 |

| EPCS-105X457 | Ф105 | 42.6 | 93.7 | 457 |

| EPCS-105X508 | Ф105 | 42.6 | 93.7 | 508 |

| EPCS-120X610 | Ф120 | 53.0 | 114.3 | 610 |

| EPCS-160X620 | Ф160 | 60.0 | 154.0 | 620 |

| Customized | Special size and packaging available on request. | |||